Overview:

Uzun + Case – Research + Design (U+C-R+D) recently teamed with the School of Architecture and School of Civil and Environmental Engineering at Georgia Tech (GT) to develop an innovative lightweight structure. Jim Case (U+C) accompanied Jonathan Desi-Olive (GT) and Michael Koliner (GT) to demonstrate the structure at the International Association for Shell and Spatial Structures (IASS) Exposition in Barcelona, Spain.

The structure is a self-erecting tensegrity module measuring 12 ft. x 12 ft. x12 ft. Which weighs only 122 lbs. To our knowledge, this is the first ever large-scale air inflated tensegrity structure.

The term tensegrity was coined by Buckminster Fuller, a 20th century innovative American architect, and is an amalgam of “tension” and “integrity”. Conceptually, tensegrity structures are ones in which the compression elements are held in equilibrium by a network of tension elements. Analogously, the human body is a tensegrity structure with bones being the compression elements and muscles, tendons and ligaments being the tension elements. By separating the compression and tension function, each element is able to do its job more efficiently. As a result, tensegrity structures are among the most efficient in terms of material utilization.

The unique aspects of this design include the following:

- Being extremely lightweight, the structure is easy to transport, and could even be delivered by drone to remote areas.

- Upon inflation, the structure erects itself and prestresses its cables, both of which are challenges using conventional construction techniques.

- The system is modular, and able to be expanded to create larger structures.

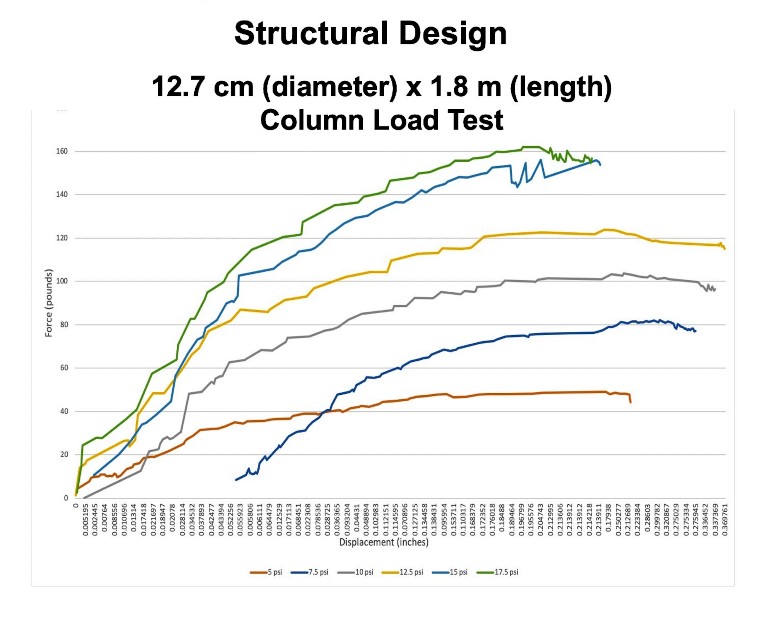

- A new inflatable fabric compression strut was developed. It is straighter and more stable than existing pneumatic components.

Conclusion:

Uzun + Case is proud of this joint effort and hopes to team with Georgia Tech on future research projects which advance structural engineering practice.