Overview:

A symbiotic relationship exists between art and engineering. On one hand, engineering inspires art. On the other hand, art inspires engineering.

Uzun + Case recently worked on the creation of two large scale art projects. Stealth is an 11 meter tall, 30,000 kilogram reinforced concrete sculpture, in Atlanta, GA, and Nimbus is a 12 meter diameter cantilevered steel structure, located in Minneapolis, MN. Both were designed by artist Tristan Al-Haddad of Formations Studio.

Stealth

The ribbon-like form of Stealth is generated by a series of lines deployed in space. These lines are in turn generators for hyperbolic-parabolic surfaces, which contribute greatly to it strength and stability. These surfaces are extruded out of plane into elliptical cross sections, enhancing stability while presenting a thin edge to the viewer. As such, the sculpture can be thought of as the deployment of a mathematical algorithm, the results of which are subjective and aesthetically perceivable.

Stealth was analyzed using the SAP2000 computer program (Computers & Structures, Inc.), with thin shell finite elements. The non-uniform thickness of the elliptical shape was modeled by varying element thicknesses, in effect creating rectangular elements which could be evaluated and reinforced by conventional means. The mesh for the finite element analysis was automatically generated from the sculptor’s computational model. Parametric modeling facilitated the refinement of the mesh and grouping of elements for analysis and design purposes.

Many options were considered for the concrete mixture. Ultimately a self-consolidating 35 megapascal pressure unit mixture with carbon black coloring was selected. Initially steel fiber reinforced ultra-high-performance concrete was considered, but not chosen due to its limited tensile strength and higher cost. Instead, conventional reinforcing was selected with polypropylene fibers added to the mixture to control cracking at thin unreinforced sections.

A primary goal of this project was to use concrete in a way that it never had been used before. This was accomplished by pushing the limits of material behavior, using the latest digital technology, and working collaboratively through all phases of the project. The result is an elegant concrete form whose beauty derives from a combination of artistic impulse, engineering skill and digital craft.

Nimbus

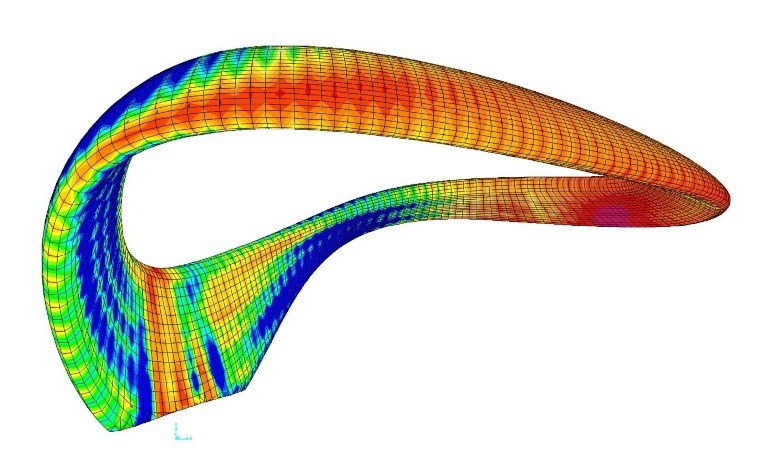

Nimbus is a 12 meter diameter sculptural canopy with a morphed toroidal geometry. It is supported from the ground at a single point. It provides a backdrop and overhead lighting for outdoor performances.

Conceptually, the overhead ring is elliptical in cross section, varying from small and shallow at its tip to large and deep at its support. This shape is reflective of the parabolic moment diagram of its cantilevered form. Based upon the need to limit weight, the structure is made of steel and is hollow.

The topology for this structure is complex, with continuously varying cross-sectional shape and orientation. The conception and development of the form was facilitated by the Grasshopper parametric modeling program (Robert McNeel & Associates) which algorithmically generated alternate configurations for consideration. Ultimately a form which best integrated function, beauty, structural integrity and buildability was derived.

Various structural schemes were considered, including a tubular steel armature clad with non-structural metal panels. Ultimately the team decided on a stressed skin design. This strategy resulted in the most efficient us of material despite somewhat complicating its structural design and fabrication.

A finite element mesh was generated from the parametric modeling program and transferred to the engineering team, which was analyzed using the SAP2000 computer program. Preliminary results indicated that the deflection and stress level of the overall structure could be easily controlled. However, localized buckling of the thin skin elements became a primary concern. Stability of the skin was studied both using a non-linear buckling analysis and by conventional moment magnification procedures.

Based upon this, an optimized scheme consisting of 2.5 millimeter through 6.5 millimeter weathering (Corten) steel plates deployed according to strength and stability criteria was arrived upon.

Conclusion:

Although very different in their conception, these projects represent the evolution of design practice toward one which is more integrated, collaborative and driven by digital technology than past paradigms. For both projects, the initial concept was simultaneously inspired by artistic intent and engineering intuition. This dual approach was made possible by parametric modeling programs which included algorithms based upon mathematics, geometry and structural behavior